The Importance of Grain Drying in Modern Agriculture

In the farming industry, ensuring the quality and longevity of harvested grains is of paramount importance. The importance of grain drying cannot be overstated as it directly correlates with the quality of the grain and the profitability of the harvest. Drying grain is not just a post-harvest activity; it’s a crucial practice that can make or break a farmer’s investment.

Understanding Grain Drying

Grain drying is the process of reducing the moisture content of harvested grains to a level that is safe for storage. This is essential because excess moisture can lead to spoilage, loss of nutrients, and the growth of mold and fungi.

The Science Behind Grain Drying

The ideal moisture content for safe storage varies by grain type but is typically between 12% to 14% for most cereals. When grains are harvested, they often contain moisture levels much higher than this threshold. For example, corn may come out of the field with moisture levels as high as 30%. To mitigate the risks of spoilage, drying grain efficiently and effectively becomes a necessity.

Why Grain Drying Matters

There are several critical reasons why grain drying is considered essential in the realm of agriculture:

- Prevention of Spoilage: Moisture is a significant enemy of grain storage. By reducing moisture levels, farmers can prevent spoilage, thus maintaining grain quality.

- Quality Retention: Dried grains retain their nutritional value better, ensuring that the harvest is not only safe for consumption but also valuable.

- Marketability: Grains that are dried to optimal moisture levels command higher market prices. Buyers are more likely to purchase grains that are well-preserved.

- Extended Storage Life: Properly dried grains can be stored for extended periods without significant quality loss, providing financial flexibility for farmers.

- Mold and Insect Prevention: Lower moisture levels drastically reduce the chances of mold growth and insect infestations.

Common Methods of Grain Drying

Farmers use various methods to dry grains, and the choice of method can significantly impact efficiency and results. Here are some of the most prevalent techniques:

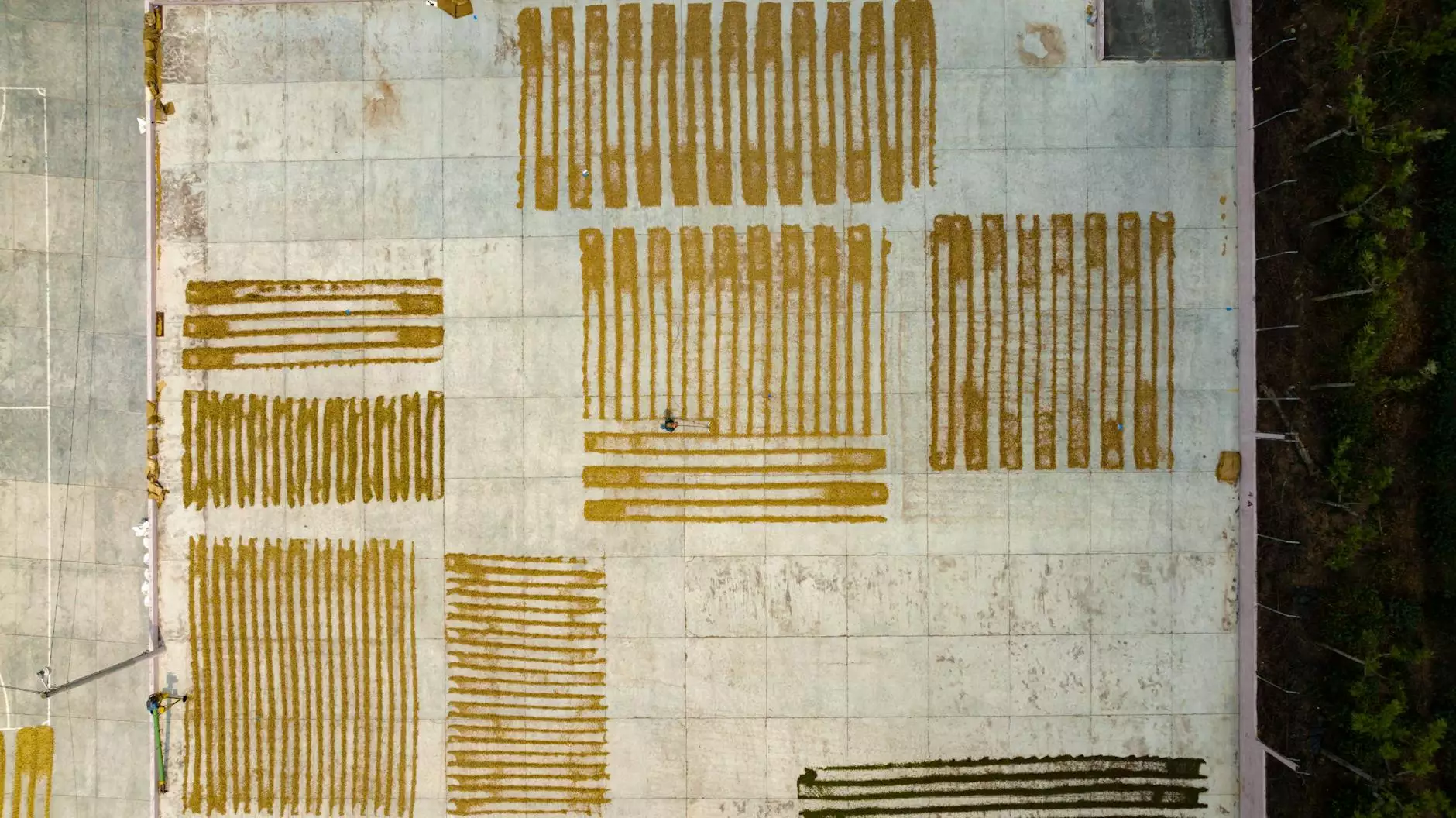

1. Natural Air Drying

This method involves spreading grains in thin layers and allowing airflow to naturally dry them. However, this method is weather-dependent and may not be suitable for all regions.

2. Mechanical Drying

Utilizing drying machines, mechanical drying is a controlled method that can effectively achieve desired moisture levels regardless of external conditions. Common forms include:

- Batch Dryers: These dryers process grains in batches, allowing for higher temperatures and faster drying.

- Continuous Dryers: For large operations, continuous flow dryers can handle a steady supply of grain, making it more efficient for high volumes.

3. Chemical Drying

This less common method involves the use of drying agents to absorb moisture. While effective, it requires careful handling and adherence to safety standards.

Best Practices for Effective Grain Drying

To maximize the benefits of grain drying, farmers should heed the following best practices:

Monitor Moisture Levels

Regularly checking moisture content using moisture meters ensures that grains are dried to optimal levels without over-drying, which can damage the grain’s quality.

Consider Temperature and Humidity

The ambient temperature and humidity levels play a crucial role in the drying process. Ideally, grains should be dried in conditions that favor moisture evaporation.

Optimize Airflow

Ensuring sufficient airflow during the drying process can enhance moisture removal and improve drying efficiency.

The Economic Impact of Grain Drying

Investing in grain drying technologies can yield substantial economic benefits. Here’s how:

Increased Profit Margins

High-quality, well-preserved grains fetch better prices in the market. By minimizing losses through spoilage, farmers can significantly improve their profit margins.

Enhanced Storage Solutions

With proper drying, storage facilities can last longer and require less maintenance, thus lowering overall operational costs.

Technological Advancements in Grain Drying

The grain drying industry has witnessed significant technological advancements in recent years. Innovative drying systems now incorporate computerization and automation. These advancements offer:

- Real-Time Monitoring: Advanced systems allow continuous monitoring of moisture levels, enabling timely adjustments during the drying process.

- Energy Efficiency: Modern drying equipment is designed to minimize energy usage while maximizing performance, making it economically viable for farmers.

- Data Analytics: Some advanced systems provide farmers with data analytics to optimize their drying strategies, predicting ideal drying times based on historical data.

Conclusion

In conclusion, the importance of grain drying in modern agriculture cannot be overstressed. It is a critical practice that affects not only the quality and safety of food but also the economic viability of farming operations. By employing effective drying methods, farmers can safeguard their investments and ensure sustainable farming practices.

For farmers looking to improve their grain drying methods and enhance their farming equipment, TSGC Inc. provides tailored solutions in Farm Equipment Repair and Farming Equipment. By prioritizing grain drying, farmers can take significant steps towards achieving higher quality outputs while maximizing their revenues.

As the agricultural landscape continues to evolve, grain drying remains a fundamental practice that supports not just farmers but the entire food supply chain. It is essential, therefore, for every farmer to understand the implications and techniques of effective grain drying.